Submersible pump - equipment for supplying clean water from a well, reservoir or well. It is used both for water supply of houses and outbuildings, and for organizing irrigation. Having made the right choice, provide the site and the house with water. If you buy a pump that is too weak, its power will not be enough to lift and deliver fluid to consumers, the pressure in the system will be below normal.

For the correct choice, if possible, compare the statistical and dynamic water levels in the well. Static - water level at rest - when it is not pumped out. Dynamic - constant liquid level with regular pumping. It varies depending on its intensity and is determined using the same pump, which is not always possible.

Buy a unit with a productivity of 5-10 percent lower than the flow rate of the well - its productivity is the volume of water that it gives per unit of time. If you buy a pump that is too powerful, the dynamic water level can drop below the level of the suction pipe, and someone will have to wait for the water level to return to wash or drink tea.

Go directly to the pump rating =>

How to Pick a Good Submersible Pump

Briefly, what is worth considering and what to look for when choosing a submersible pump.

Pump type

Submersible pumps for raising clean water work according to four principles, each with its own characteristics that are worth knowing about.

Centrifugal (also called borehole) - dynamic vane units, are widely used in suburban areas. Designed for continuous operation and virtually no noise. The liquid is supplied by the blades, which are equipped with the rotor of the electric motor. Due to the high rotation frequency, they create a zone of increased pressure at the walls of the nozzle, due to which the liquid is pushed towards the outlet.

Vibrating - budget devices operating at the expense of a rubber membrane. It reciprocates at a frequency of 50 times per second. Moving in the direction of the armature, the membrane creates a vacuum in the chamber, as a result of which water is sucked into it. In reverse movement, the inlet valves close, the pressure rises, and the water is pushed into the pressure line. Features: simplicity of design, maintenance-free, high reliability - no bearings, nothing heats up. Not applicable for wells.

Screw - pumping liquid by pumping it with helical rotors rotating in the stator. The rotor moves along the grooves cut for it or is in close contact with the body, excluding the return of fluid back into the well. It copes well with water with a lot of abrasive particles - grains of sand.

Vortex - form a pressure impeller with blades inclined to its axis. There is no gap between the latter and the walls, which excludes the return movement of water. Due to the rotation of the impeller, the liquid is directed to the outlet pipe under a stronger pressure than in analogues.

Performance

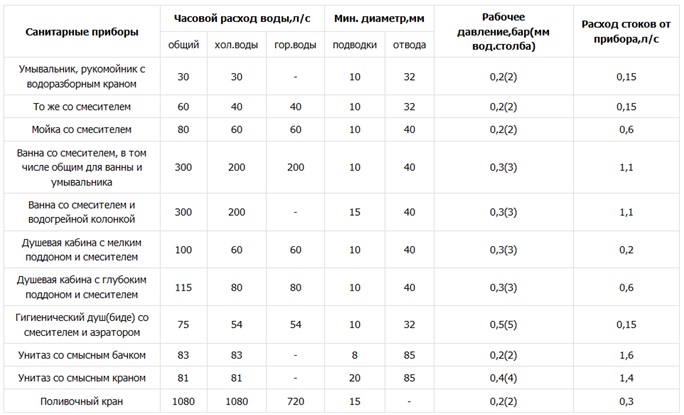

It is calculated approximately based on the number of consumers. The water flow must be lower than the flow rate and pump performance. You can use the table for assessment.

According to statistics, a family of 3-4 people living in their own house regularly spends about 70 liters of water per day, excluding watering, car washing, etc.

Lifting height

The depth of the well varies from the water table to the surface of the earth. To it is added the transfer of fluid along the site in the vertical and horizontal directions. The lifting height is calculated according to the scheme: 1 bar = 10 meters well depth plus 2-3 bar to maintain pressure in the system. And do not forget to throw 20-25 percent in reserve, so that at the end point of the water intake (on the second floor or at the end of the site) there is a normal pressure.

Diameter

Matched to the diameter of the siege pipe with a small gap - needed for heat exchange between the unit and the environment.

With a low flow rate, you will have to choose: a low-performance pump or intermittent cycles of its operation during intensive operation (watering). Do not forget about the sensitivity of the device to sand particles. They are not a hindrance to the screw ones, but they wear out the vortex ones at an accelerated rate.

Water intake

Devices with a top fence can be installed on the bottom: this is will eliminate the load on the cable and reduce the likelihood of getting inside the bottom sediment... The intake from the bottom is relevant for wells with low flow rates - they will increase their productivity and release reservoirs. Remember that many models are designed for liquid cooling - they need full immersion (applies to models with a bottom intake).