A resident or owner of a country house must have a good welding inverter. Without it, you can't repair a car, don't put up a fence, don't weld an arch for grapes or a trailed tool for processing a plot. Before buying, a problem arises: you need to decide which inverter to choose for your home, when should you give preference to arc welding, and when - argon, what parameters should be taken into account? We will tell you everything in order, and do not forget to mention reliable manufacturers.

When choosing a welding inverter, you need to know the basic rule - the value of the current strength affects maximum electrode diameter, in turn, the diameter of the electrode affects the maximum thickness of the welded material (axiom for manual arc welding). For example, for a profile with a thickness of 3-4 mm, it is necessary to use an electrode D = 3mm, and the current strength should be 80-130A. The dependence is straight, the smaller the electrode, the less is needed amperage... In turn, amperes affect the power of the inverter. In our rating, we have selected the best inverters with used electrodes up to 5 mm in diameter for manual arc welding. In addition, the best semi-automatic and universal welding inverters (TIG, MIG / MAG, MMA) have been identified.

Go directly to the rating of inverters =>

For novice welders - inverters are the best choice, since these machines have very useful functions on board that facilitate the welding process: forced arc, hot start, anti-sticking. In addition, be sure to use a protective mask, protective clothing and gloves (gaiters).

Proceeding from the fact that the welding machines were selected for household needs in the TOP manufacturers, we did not include the famous brands EWM, Kemppi due to the very high price, although these companies are undoubtedly leaders in the production of welding equipment.

How Do I Pick a Good Welding Inverter?

Inverter - a welding machine common in everyday life and small-scale production. It is used for manual arc welding of mainly ferrous metals, it is convenient for transportation and work in hard-to-reach places (on stairs, on scaffoldings, holding the apparatus on itself). The work algorithm is as follows:

- AC mains current 50 Hz is smoothed by a filter and rectified;

- direct current is converted back to alternating high-frequency (tens of kHz);

- AC voltage drops to 60-90 V;

- the current rises to the required 40-250 A.

Thanks to the high-frequency current, a good welding inverter has advantages over other machines:

- ease of learning and operation for beginners;

- availability;

- light weight and dimensions;

- Efficiency is about 90%;

- demonstrates a stable arc with voltage dips up to ~ 180 V and surges up to 240 V;

- smoother and more uniform seam than when using transformer models;

- electronics allows you to adjust the current strength in a split second;

- additional functions.

Among the disadvantages:

- afraid of dust;

- professional models are more expensive than other devices of the same class;

- at temperatures below -12 ... -150 C don't always work well;

- high repair costs.

Of the features - it is not recommended to use cables longer than 2.5 m.When working, it is worth considering the factor PV - duration of inclusion - for the house, he does not play a special role.

Household devices differ little from each other, but even a small difference in characteristics can play a big role.

- Welding current - depends on the thickness of the welded parts, metal. The approximate relationship is shown in the table below.

- Open circuit voltage determines the ease of ignition and stability of the arc.It is in the range of 40-90 V. Above - it is better to work, especially for a novice welder.

- Supply voltage - inverters are good because they work stably with voltage dips up to 20-25%: 180-190 V and surges up to 10% - 240 V. If you take for rural areas, you live far from the transformer box - look at this indicator.

- Operating mode at maximum current - duration of inclusion, or PV. Defined as the time the inverter can boil at peak current without overheating. Specified as a percentage on a 10-minute interval: 60% means the weld can be continuously operated at rated load for 6 minutes, then it needs to cool for 4 minutes under normal conditions. In hot and cold weather, the meaning changes.

Additional features make life easier for a beginner:

- Antistick - prevents the electrode from piercing if it sticks by reducing the current to a couple of amperes.

- Hot start or "Hot start" - the arc is ignited at an increased current to facilitate welding of cold metals.

- "Arc Forcing" - will reduce the likelihood of sticking the electrode when it comes into contact with the metal by increasing the current.

We have already covered:

Inverter types

Inverters are divided according to welding technology.

Manual arc welding (MMA) - an economical household unit for carrying out work in the house, in the country and in the apartment, to which high requirements are not imposed.

The seam needs processing - cleaning, slag removal.

Semi-automatic welding (MIG / MAG) - larger and more massive MMA devices, made on the basis of transformers, are used in service centers, in production. They are cooked with a special filler wire with automatic feed in a protective inert / active gas. When working in a gas-free environment, flux cored wire is used.

They require additional consumables - gas (carbon dioxide, argon). They are used where speed of work is important, you need to cook stainless and thin steel, aluminum - auto repair.

TIG welding - units for welding with non-consumable (tungsten, carbon) electrodes in protective gas.

Ensures a high quality seam, splash-free and metal oxidation-free welding, with minimal slag formation. The work speed is low. The device is practical when working with non-ferrous metals, their alloys, in the production of small parts and structures.

Universal welding inverters - combine two or more methods of metal welding.

They are mainly used in industries and in car services, where several welding methods are needed (stainless steel, non-ferrous metal, thick and sheet metal) and metal cutting.

Top product manufacturers

All, with rare exceptions, devices on the domestic market are manufactured in China under the customer's license. The quality of components and assembly depends on both the customer and the manufacturer. There are little-known Chinese companies that make devices in their homeland that work for years. Among dozens of manufacturers of welding inverters, they have proven themselves from the best side:

- Fubag Is a German company widely represented on the European market. Has dozens of patents and 19 factories in Germany and Switzerland. Renowned for the durability of products meeting all ISO points.

- Elitech - produces affordable goods that undergo multi-stage quality control. The equipment is distinguished by exquisite design, durability and quality of components.

- Wester - a domestic manufacturer successfully competing in the domestic market with European welding.

- FoxWeld ("Foxveld") - offers devices manufactured according to Italian technologies in China. Manufactures welding units for any application.

- "Svarog" - the Chinese manufacturer Jasic, represented on the Russian market under the Svarog brand. Provides a wide range of welds for industry and household needs. Owns four research centers, three factories and 50 patents.

- Resanta - the Latvian brand, firmly entrenched in the Russian market, was one of the first to present inverter welding, making them accessible to the average man in the street.

Best Welding Inverter for Manual Arc Welding

The best choice for occasional use at home and in the country.

Fubag IR 200 (MMA)

A household welding inverter with a peak current of 200 A, capable of working with electrodes up to 4 mm in diameter. With it, you can easily weld a reliable structure from a thick-walled profile and you will be able to cut metal, for processing which several disks from the angle grinder leave. The digital display shows the current to the nearest ampere. Supports all advanced unit options: forced arc, hot start, anti-stick. Lightweight and adjustable shoulder strap make it easy to carry and handle on your shoulder.

Features:

- digital screen;

- options to facilitate work and improve the quality of the seam;

- thermal protection and forced cooling;

- arc stability at a voltage of 150-240 V.

Svarog REAL ARC 200 (Z238N) (MMA)

Welding machine for household and professional purposes, for working with thin and thick (up to 8 mm metal). The optimized antistick option allows you to quickly tear off the electrode, even if it is stuck. Rubberized grips and a regulator do not slip out of gloved hands. The insulation of cables does not dazzle in the cold, making constant movement comfortable. The arc burns stably with significant dips and voltage surges: 160 - 250 V.

Features:

- quick disconnect cables for polarity reversal;

- power and overheating indicators;

- peak current rarely exceeds 180 A;

- downwardly directed grilles prevent dust from entering the case;

- no carrying strap.

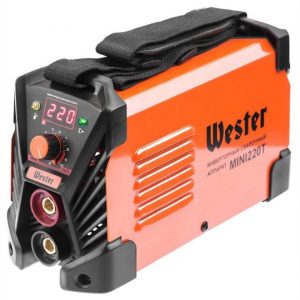

Wester MINI 220T (MMA) - excellent current setting accuracy

Stylish machine with a three-character seven-digit display for precise setting of the welding current. Designed to work with fusible electrodes up to 5 mm in diameter. Electronics stabilizes the arc in case of voltage dips up to 165-170 V, which is important for country houses, summer cottages and garage cooperatives located on the outskirts of the city. A hot start will make it easier to handle poor quality (wet) electrodes and bad (rusty) surfaces. The function of resetting the current and voltage when the metal comes into contact with the electrode will quickly eliminate its adhesion.

Features:

- overload protection;

- forced cooling;

- anti-sticking and fast ignition of the arc;

- turn-on time - 60%;

- low voltage stabilization.

RESANTA SAI-190K (MMA), Compact version

A budget but reliable inverter with a circuit based on innovative IGBT transistors. Works in low voltage household networks. The thermal sensor will turn off the device when it gets too hot, preventing thermal destruction of the power elements. The case is designed for efficient cooling, protecting the components from external influences, including falling water drops and small objects.

Features:

- overheat protection;

- anti-stick and hot start system;

- adjustable carrying strap;

- easy cutting of metal at high current;

- functioning with voltage dips.

Sibrtech IDS-190 (MMA) - a good and inexpensive device

Inexpensive inverter with acid green housing and bayonet connectors for fast polarity reversal.Short and unreliable cables should be replaced immediately. The practical, adjustable strap makes it easy to carry the machine around the construction site. Downward facing ventilation grilles protect the electronics from small objects and vertically falling water drops. Indicators visualize power availability, overheating and overload

Features:

- light arc ignition;

- anti-sticking of the electrode;

- protection against overheating and power surges;

- mask included.

RESANTA SAI-190 (MMA) - full-size

Welding inverter for home use, allowing short-term welding with a 5 mm thick electrode. At the same time, it has a long turn-on time - 70% at a temperature of +400 C - even in hot weather, you can put up a fence or weld a frame without much delay. The case is protected from small objects and rain, but it is not recommended to turn on the device in case of precipitation. Thermal protection turns off the device when a critical temperature is reached and will not allow it to be turned on until it cools down.

Features:

- operating voltage - 140 - 240 V;

- working cycle - 70%;

- short wires;

- network and overheating indicators;

- hot start, arc forcing and anti-stick.

BISON MASTER MMA CA-190K (MMA)

A good welding inverter, an assistant for a summer cottage, garage and home, designed to work with fusible electrodes up to 4 mm thick. Supports all advanced technologies in the field: anti-sticking - lowering the current when sticking to quickly detach the electrode, arc afterburner - to prevent sticking and hot start - simplifies the formation of an arc discharge. High-quality components and IGBT transistors stabilize arcs at voltages from 160 to 240 V. The electronics are protected from dust with a high-temperature varnish, and from overheating - by a high-speed fan and thermal sensor.

Features:

- technologies to facilitate welding;

- thermal and dust protection;

- arc stability;

- possibility of power supply from the generator;

- fan and IGBTs increase performance.

Best Semiautomatic MIG / MAG

The device will allow to partially automate and speed up the process of joining metals.

Aurora OVERMAN 205 (MIG / MAG, MMA)

The best welding semiautomatic device for welding with consumable electrodes and wire with and without a shielding gas (flux wire). The knobs regulate the supplied current and voltage. The inductance regulator changes the current in a small range, adapting the seam to the welding conditions: high or more diffuse and wide. Works in networks with voltages from 140 V and generates current up to 165 A - works with 4 mm electrodes. Long run times for industrial applications guarantee improved cooling.

Features:

- stable operation in low-voltage networks;

- fine adjustment of the current;

- cooling by a fan and four radiators;

- improved air inlet tunnel.

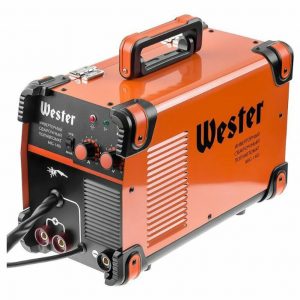

Wester MIG 140i (MIG / MAG, MMA)

A good semi-automatic welding machine for electrode and wire feed. With a peak current of 140 A, it will reliably weld metal up to 5 mm thick. Indicators indicate power supply and overheating. The red button will turn on and off the unwinder mechanism. With a duty cycle of 60%, it is great for home and garage, in production (car repair, manufacture of thin-walled metal structures) it is useful if you weld thin parts.

Features:

- current and voltage regulator;

- excellent welding in the MIG / MAG mode;

- quick disconnect cables for polarity reversal;

- protection against thermal destruction of electronic components;

- control of the feed rate of the filler.

STAVR SAU-200M (MIG / MAG, MMA)

Semi-automatic inverter for manual arc and gas welding. The representative of the new line is made on an updated technological base - IGBT transistors. They stabilize the arc during voltage surges, are less sensitive to thermal breakdowns and overloads, and improve the seam. There is a wire unwinding regulator, an overload and power indicator. At the bottom of the control panel there is a reminder for choosing the current corresponding to the thickness of the filler material: electrodes, flux and non-flux wire.

Features:

- options to simplify work: hot start, anti-stick, arc force;

- undervoltage stabilization;

- work with a wire up to 1 mm and an electrode up to 5 mm;

- thick copper cables of 2 m.

Rating of universal welding machines TIG, MIG / MAG, MMA

Multifunctional welding for manufacturing, motorist and handyman.

Fubag INMIG 200 SYN PLUS (TIG, MIG / MAG, MMA)

Argon-arc welder from a renowned German manufacturer for welding with non-consumable and covered electrodes, wire at a current up to 200 A for all modes. The display allows you to fine-tune the parameters and select the operating mode of the device to obtain a high-quality seam. Supports dozens of adjustable parameters: soft start, pre and post-purge, inductance, current, wire unwinding speed, arc voltage. Synergic mode for MIG adapts current and arc length to consumable, metal type and thickness.

Features:

- synergistic mode;

- full display for customization;

- slow polarity reversal;

- overheating indicator and thermal protection;

- high quality adjustable unwinder.

Aurora SPEEDWAY 200 Synergic (TIG, MIG / MAG, MMA)

A durable professional model for a wide range of production tasks, where quality and aesthetics are emphasized. It has a synergistic control - the operator will select the welding mode by turning one handle. Famous for the ROOT Low Spatters option, it reduces the energy of spray dispersion, does not require post-processing of the seam, and improves its quality along three axes. The algorithm is based on continuous control by a microprocessor for the creation, separation and delivery of metal drops to the surfaces to be welded.

Features:

- microprocessor control of welding;

- ROOT Low Spatters mode;

- option for manual adjustment of factory settings;

- work with all types of filler wire.

FoxWeld InverMig 185 (TIG, MIG / MAG, MMA)

Reliable oversized semiautomatic device for a small production workshop or a business in a garage. Supports manual stick welding, semi-automatic flux and cored wire in a shielding gas atmosphere, argon arc. Allows rapid polarity, amperage and inductance changes to control the arc and reduce spatter. 100% duty cycle allows you to work almost all day without stopping.

Features:

- effective cooling;

- continuous operation;

- ideal CVC for all modes;

- smooth wire feed;

- contact arc ignition.

RESANTA SAIPA-190MF (TIG, MIG / MAG, MMA)

A universal welding unit from a renowned manufacturer for welding aluminum, cast iron, sheet materials, various grades of steel and cutting metal. TIG welding will allow joining alloy steels and a variety of non-ferrous metals. Powerful cooling copes with heat dissipation, extending the duty cycle by up to 70%. Thermal protection turns off the power until the power elements cool down. The front panel is equipped with a regulator of the wire unwinding speed - respectively, the current, arc voltage - controls the depth of welding, the button for feeding the filler material (in MMA mode - current).

Features:

- short cable with bursting insulation;

- 2-stroke and 4-stroke welding;

- arc afterburner option;

- control of the depth of boiling in TIG mode.

An inverter for manual welding is relevant in everyday life, a semiautomatic device is in production with small volumes and in a car workshop. Universal welding is more suitable for business.

Video: How to choose a good welding inverter