A miter saw is a useful thing, but for a home craftsman this is an expensive purchase, and it is not clear whether to take a saw with a broach, will it be useful on the farm later? Another thing for a professional is an irreplaceable handy tool for a complex high-quality cut. With the support of our partner (online tool store), we have tested and learned how to choose the best miter saw for home and professional use.

Miter saw - an electric saw with a disc as a cutting tool, designed for cross-cutting (facing) sawn timber. It is mainly used for precise cutting and trimming of lumber and wood-based materials for sale, on construction sites, in carpentry shops, in production. When equipped with appropriate discs, it cuts profiles made of aluminum, copper, their alloys, various plastics. There are powerful models for cutting metal profiles, pipes.

How to choose a good miter saw

Approach the choice of trimming with a clear understanding of the tasks that it must solve, in what conditions you will have to work.

The main characteristic of the saw is not a technical indicator (figure), but quality of its manufacture, assembly. It is reflected in durability, accuracy and usability. Among the technical characteristics, pay close attention to the following.

Electric motor power - is responsible for the duration of the working session and durability. The more powerful, the more you can work with the saw without stopping to cool down, it will last longer. For a personal workshop, a device with a 1.2-1.3 kW motor is enough, for large volumes and regular work, take a more powerful one - 1.5-1.8 kW.

Saw blade diameter - is responsible for the cutting depth - depends on the dimensions of the material being cut and the power of the motor. They fluctuate in the range of 210-350 mm. For an approximate calculation, divide the disc diameter by two and subtract about 20-25% (the exact value individually, depends on the design features of the model).

Models with a broach will allow you to cut thicker and wider boards, timber.

RPM or idle frequency - engine speed. Affects the quality of the cut, depends on the parameters of the engine - if the rpm is high, and the motor is low-power, the rotational speed of the disk under load is noticeably reduced. It fluctuates around 2800-6000 rpm. In advanced models, there is a speed regulator (usually a variable resistor that reduces the motor power).

Other features and options

In addition to the main indicators, there are a number of other criteria that will facilitate the work with the tool and make it convenient.

Kerf width - depends on the material being processed and the size of the disc - its thickness and diameter. It fluctuates in the region of 2.7-3.3 mm and more.

Power type - in addition to the network tools, there are also rechargeable tools - they are convenient when working at the facility, but they need regular battery charging.

There are many varieties and design features.

- vacuum cleaner connection;

- feed function - the ability to move the saw headset with a motor along the guide to increase the cutting width up to 340 mm;

- illumination of the cutting line with a laser beam;

- inclined cut - allows you to cut at various angles in the vertical plane - the disc tilts to the right and left;

- angle of rotation of the table;

- bed material - for reliable saws it is magnesium, pure aluminum or alloy, for inexpensive ones there is plastic;

- transmission type - through a gearbox, belt and directly.

Many models come with a small table for small workpieces. For trimming long lumber, plastic and aluminum profiles, you will need additional receiving and feeding tables with rollers and the ability to install a stop - for cutting blanks to size without preliminary marking.

For many carpenters, an upper sawing table or stand is useful (you can do it yourself) - represented by a platform above a disc with a parallel stop, a ruler and a riving knife (not always). Allows you to unfold short workpieces without moving around the workshop.

There are models with digital display of tilt angles for unprecedented sawing accuracy, cutting depth limiter - for carpentry work, cutting out quarters from the butt and grooving. The soft start option will reduce the initial load on the mechanics.

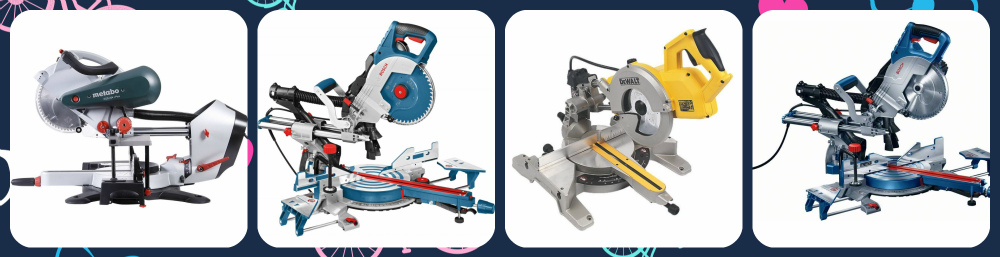

Top Miter Saw Manufacturers

For home (for yourself), an inexpensive tool with a mediocre assembly is also suitable, and for production it is better to purchase a facing from a well-known brand. About a dozen brands have proven themselves. Among the more expensive but reliable Hitachi, Makia, Metabo, Bosch... Cheaper DeWALT, domestic Anchor and Bison... The latter provide a 5-year warranty.