A good semiautomatic welding machine is a versatile unit capable of solving a wide range of tasks for joining metals using filler wire and shielding gas (MIG / MAG). When using flux-cored (flux-cored) wire, they do without it. Almost all semi-automatic machines operate in the mode of manual arc welding with covered electrodes (MMA). In addition to their versatility, they are distinguished by high productivity, the ability to form long continuous seams that require minimal subsequent processing. Consider which semiautomatic device to choose for a subsidiary farm, small production, garage, service station and construction site.

Go straight to the rating of semi-automatic machines =>

- How to choose a good semi-automatic welding machine

- Which semiautomatic welding machine to choose

- Wire diameter and amperage

- Choosing the right shielding gas

- The best welding semiautomatic devices MIG / MAG, MMA

- Rating of universal semi-automatic machines TIG, MIG / MAG, MMA

- Video: How to choose a good semiautomatic inverter

How to choose a good semi-automatic welding machine

Semi-automatic welding machine got its name from the automatic filler wire and shielding gas feed mechanism. Pressing the torch trigger starts the miniature electric motor, as a result of which the unwinder feeds the wire at a constant speed through the metal channel to the welding zone. In parallel, a valve is activated, which supplies argon, carbon dioxide or their mixture to the welding bath. Gas and wire feed rates are adjustable.

What can be cooked with a semiautomatic device? Semi-automatic inverter machine allows you to weld thick metals, cast iron, aluminum, stainless steel, sheet materials. The seam practically does not need to be processed - the formation of slag is minimal. Also, continuous and uniform feeding of the electrode wire speeds up the process of joining metals, allows you to apply long continuous seams. For welding fences and non-critical ferrous metal products, it would be more expedient to choose MMA inverter (for manual arc welding).

Power. Determines the productivity of welding, the maximum thickness of the welded metal. Indicated in kW. The effective power is always lower than the consumed power - part of the electrical energy is converted into heat.

For home use, the device is sufficient power of 3 kW. This is enough for welding non-critical structures from a profile up to 2.5 mm thick, repairing a tank or the bottom of a car. If you work with thicker metals - 4 mm, take the device power 3-5 kW... For melting thick-walled products (about 6-10 mm), a device with a capacity of 6-8 kW and above is needed.

Welding current.Determines the maximum thickness of the material to be welded. If it is not enough, the seam will remain on the surface of the parts to be joined, it will be easily damaged. At current (approximate data):

- 110-120 A you can work with wire with a cross section of 0.6-0.8 mm and weld metal up to 2.5 mm thick;

- 120-160 A - the diameter of the wire is 1 mm, the thickness of the welded metal is up to 4 mm;

- 160-200 A parts with a cross section of up to 4-5 mm are welded using a wire with a diameter of 1.2 mm.

Pay attention to the minimum welding current. It is important when working with thin sheet metals, small parts.

Current regulation. The regulator knob changes the current strength to adapt the parameters of the electric arc to the characteristics of the workpieces. Toggle switches are adjustable in steps - each step adds or decreases the indicator by a few (50-10 A) or smooth - in steps of 1 or less amperes. For high accuracy and clarity, it is worth purchasing models with digital indication of current strength.

Voltage. For the private sector, the mains voltage indicator is important.With a standard value of about 220 V, it often drops below 200, and even 180 V. When choosing, take into account the remoteness of the house or garage from the transformer from which electricity is supplied to your site. If the mains voltage is too low, take a device that can stabilize this indicator. Do not trust manufacturers who guarantee excellent performance of inexpensive welding at 160 and even 140 V.

The ease of striking the arc, especially by beginners, and its elasticity depend on the no-load voltage. The lower the value, the cheaper the device.

Other points. When choosing a good semiautomatic device, look at the parameter of the duration of the on (DC). For household appliances, it rarely exceeds 30-40% in MIG / MAG mode, and this is normal. This means that after 3-4 minutes of operation at peak current, the device needs to cool down for 7 or 6 minutes, respectively. For a house and garage, this is enough, but for a production unit, the PV should be from 60%. For MMA mode, the figure may be higher.

Which semiautomatic welding machine to choose

For a subsidiary farm, a garage and a summer cottage, an apparatus with a capacity of about 3 kW with a maximum welding current of 120-160 A is enough. Choose the minimum value based on the thickness of the metal to be welded. PV is 30-40%. It is important to work with voltage dips up to 200-190 V.

For a garage, a small workshop with a commercial slope or a service station, buy a 4-5 kW welding with a peak current of 160-200 A, a minimum of 10 A and a duty cycle of 60-70%. A connector is required for connecting an electrode holder for manual arc welding with consumable electrodes.

For professional needs, you need a powerful and expensive device with a current strength of over 200 A, an on-time from 80%, preferably liquid-cooled. The power can reach 7-8 kW or more. MMA support and a Euro connector are required.

Wire diameter and amperage

| Metal layer, mm | Current, A | D wire, mm |

| 0,5-1 | 10-30 | 0,6 |

| 1,2-2 | 45-100 | 0,8 |

| 2,5-4 | 120-200 | 1-1,2 |

| 5-8 | 150-350 | 1,6 |

| 9-20 | 300-500 | 1,6 |

We have already covered:

Choosing the right shielding gas

To protect the weld pool from atmospheric gases, inert gases (argon), carbon dioxide or their mixture are used - the molten metal does not interact with them. It is supplied from a gas cylinder connected to the burner. The gas is selected based on the welding conditions:

- Carbon dioxide - inexpensive, suitable for non-critical joints that will not experience significant loads, welding thin ferrous metals with a thickness of about 1 mm. When working, splashes scatter, the seam turns out to be "penny", not aesthetic.

- Argon - expensive gas for welding alloyed and stainless steels, titanium, aluminum, copper, alloys based on them.

- A mixture of carbon dioxide and argon (usually in a ratio of 1 to 5) - Provides a soft and stable arc, a smooth, beautiful connection that does not require post-processing, reduces metal spatter. Suitable for handling alloyed and high carbon steels.

The best welding semiautomatic devices MIG / MAG, MMA

Gas shielded and manual welding devices with consumable electrodes.

Aurora OVERMAN 205 (MIG / MAG, MMA)

Lightweight semi-automatic welding machine with the ability to weld with stick electrodes. Works with self-shielded flux-cored wire. With a current of up to 200 A and a power of up to 8 kW, it will become a reliable assistant in a garage or a production workshop with a significant amount of work. It has proven itself excellently when welding aluminum - suitable for auto repair shops and service stations. Long turn-on time is provided by an updated cooling system based on four radiators.For operation at low temperatures, a socket is provided for connecting the heating of the gearbox. The device is afraid of voltage drops up to 160-140 V.

Features:

- current and voltage regulator;

- inductance control;

- reducer heating option;

- polarity change on the case.

Svarog REAL MIG 200 (N24002N) (MIG / MAG, MMA)

An advanced unit for household and industrial use. The torch is equipped with a hook that snaps onto just about anything. The front panel contains regulators: voltage in MIG mode, wire feed speed, inductance (arc afterburner). The latter option stabilizes the arc, eliminates sagging when welding thin metals. For the MMA mode, there is a current regulator in the range of 10-160 A. Under the housing cover, there is a table with the recommended welding modes: correspondence of current, metal thickness and wire / electrode.

Features:

- welding of aluminum;

- work with flux-cored wire;

- afterburning the wire;

- many regulators;

- dry run of the welding wire.

RESANTA SAIPA-220 (MIG / MAG)

A powerful unit for solving any tasks for welding metals in a protective gas environment. Equipped with temperature sensors. They monitor the thermal regime of the transformer, and if its temperature approaches a critical value, turn off the power supply. Overheating will be notified by an alarm indicator. The body is coated with a dielectric compound. Under its cover there is a drum with a wire, a mechanism for controlling the speed of its unwinding and a gas metering valve. To increase the duty cycle, the transformer housing is made of aluminum, which perfectly conducts thermal energy.

Features:

- arc voltage control;

- welding only in modes with shielding gas;

- prevents overloading in the power grid during arc striking;

- thermal protection forcibly cuts off power when overheating.

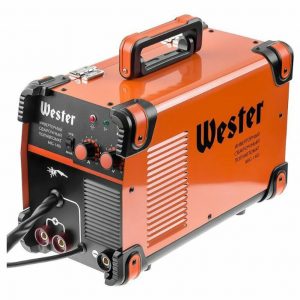

Wester MIG 140i (MIG / MAG, MMA)

Inexpensive semiautomatic device of inverter type with an output current of 140 A for domestic needs. It works with wire with a cross section of 0.6-0.8 mm and welds with stick electrodes 1.6-3.2 mm thick. With such parameters, it perfectly welds steel up to 6 mm thick, which is quite enough for home use. Effective cooling and high-quality components ensure a duty cycle of 60%. Stepless adjusters control current and wire feed speed. Indicators indicate power supply and overheating.

Features:

- quick detachable cables;

- forced cooling;

- long working cycle;

- control of current, voltage, filler feed.

Fubag IRMIG 180 38608.3 (MIG / MAG)

An inexpensive semiautomatic device with a productivity of 40% in MMA mode and 25% in MAG mode will become an indispensable assistant in a small workshop, garage and subsidiary farm. Knobs for MMA current, filler wire feed speed and voltage for MIG / MAG modes allow you to adapt the welding mode to any workpiece. With bayonet connectors, quickly connect cables and reverse polarity for working with thin walled and thick workpieces. The yellow indicator will inform about the overheating of the device, which is monitored by a thermal sensor with a microcontroller.

Features:

- overload protection;

- stepless regulators;

- quiet work;

- welding with wire and covered electrodes;

STAVR SAU-200M (MIG / MAG, MMA)

The TOP is completed by a budget welding machine for joining metals with copper wire in an environment of protective gases and covered electrodes. The electronic filling is based on innovative IGBT transistors that are resistant to overload and heat. Welding current, wire unwinding speed are changed by regulators on the front wall. Supports cored wire welding without shielding gas. Supports anti-stick, arc afterburner and hot start. Suitable for small batch production thanks to a 60% switch-on time.

Features:

- stability of work with voltage drop up to 25%;

- welding with consumable electrodes and flux cored wire;

- long turn-on time;

- production based on IGBT transistors;

- functions to facilitate work: anti-sticking, arc afterburner, hot start.

Rating of universal semi-automatic machines TIG, MIG / MAG, MMA

Multifunctional semi-automatic inverters that allow additional welding of metals with non-consumable electrodes in an atmosphere of shielding gas or gases.

Fubag IRMIG 200 SYN 31447 + torch 38443 (TIG, MIG / MAG, MMA)

An upgraded version of Fubag IRMIG 180 with three types of welding, increased peak current and a digital display, the latter will help you choose the welding mode that is most suitable for the current conditions: the wire unwinding speed (in MMA mode - welding current), arc voltage and inductance are regulated. In synergic mode, you can specify the wire diameter, type of shielding gas. Heat-resistant plastic bayonet connectors allow you to quickly reverse polarity and get the device ready for use. The wire unwinder is designed for diameters of 0.6 - 1 mm.

Features:

- synergistic management for newbies;

- three welding modes in one device;

- fast and reliable connection;

- the VRD option lowers the voltage to a human-safe value when idle.

Aurora SPEEDWAY 200 Synergic (TIG, MIG / MAG, MMA)

Professional assistant in the workshop and on the construction site, allowing you to weld with self-shielded flux-cored wire, stick electrodes, MIG / MAG wires and non-fusible electrodes in argon atmosphere. There is only one knob on the front panel, the control is completely synergistic: you select the operating mode and rotate the regulator, the microprocessor selects the operating parameters automatically. For the pros, making adjustments to the standard settings is provided. The Root mode is noteworthy: it reduces the amount of splashes by half, stabilizes welding in any position, and practically eliminates post-processing of the seam.

Features:

- support for ROOT Low Spatters technology;

- 2-stroke and 4-stroke operating modes of the burner;

- quick change of polarity;

- power unit based on IGBT technology.

Svarog PRO MIG 200 (N229) (TIG, MIG / MAG, MMA)

High-quality machine for semi-automatic welding in an atmosphere of shielding gas, gas-free flux-cored wire, covered electrodes and argon arc welding. It will be needed in a car workshop, on a construction site, in a small production. Works with wires with a diameter of 0.6-1 mm. There is a synergistic and manual control of the arc parameters, the functions of an idle wire run and gas blowing. The Arc Force option will reduce the likelihood of electrode sticking when a drop of metal separates or the electrode approaches the surface to be welded.

Features:

- lowering the open circuit voltage in idle mode;

- turn-on time - 60%;

- 5-year manufacturer's warranty;

- SMT-mounting with electronics coating with protective varnish;

- synergistic management;

- burner modes 2T and 4T.

RESANTA SAIPA-190MF (TIG, MIG / MAG, MMA)

Multifunctional instrument with 70% duty cycle. Its front panel contains connectors for cables and controls: voltage, wire feed speed, torch mode (2T / 4T) for MIG / MAG welding, the current changes automatically. For TIG and MMA modes, current control and arc afterburner control are available. Hot start and anti-stick functions make the job of novice welders easier. The design of the case prevents vertically falling raindrops and large objects from getting inside.

Features:

- forced wire pulling;

- overload protection;

- IGBT transistors;

- increased parameters of electrical safety;

- duration of inclusion - 70%.

The rating contains the best welding semiautomatic devices capable of solving any problems, except for the most highly specialized ones, in the field of welding metals in everyday life and in small industries. When choosing, be guided by the scope of application: scope of work, type and thickness of metal, stability of the input voltage.

Video: How to choose a good semiautomatic inverter